We're hiring!! Come join us as we shape the future of thermal technology - Apply Now

Additive manufacturing (AM), also referred to as 3D printing, is a new technology that enables the design and production of shapes and forms that are not possible with traditional manufacturing.

Where traditional manufacturing uses a process where several parts are joinedtogether or cut away from a solid block of material (subtractive process), additive manufacturing uses an additive process. This is where parts are built incrementally, layer by layer, and often produced as a single piece rather than many.

This new approach has allowed for profound shifts in development and resulting complex geometries can now be made with several benefits. Although believed by many, it is not possible to print everything using additive manufacturing. At Conflux we are thermal pioneers continuing to push the limits of what additive manufacturing can do for heat transfer solutions.

Additive manufacturing is often referred to as 3D printing and is a new technology that enables the design and production of shapes and forms that are not possible with traditional manufacturing. Although often seen as the same, some schools of thought separate the two. 3D printing, being a process where a product is built layer-by-layer and additive manufacturing, where a product is made by being added (additively) to which might be layer by layer but not restricted to this.

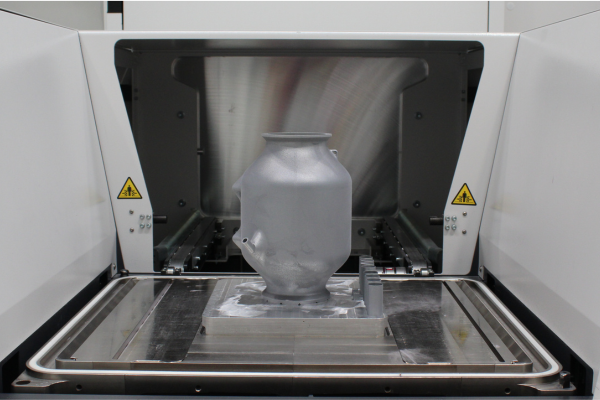

Additive Technologies include vat photopolymerisation, material extrusion, material jetting, binder jetting, powder bed fusion, directed energy deposition, and sheet lamination. At Conflux, we use a layer-by-layer build process known as Laser Bed Powder Fusion (LBPF) as our metal additive manufacturing technology. To create the desired three-dimensional object, this process uses a fibre laser to selectively melt fine metal powder to form the shape.

We have selected LBPF due to its ability to create the fine geometries and durable heat exchangers.

Laser Bed Powder Fusion (LBPF) is layer-by-layer additive metal manufacturing technology that uses a fibre laser to selectively melt fine meal powder to form the desired 3D object. In this technique the laser beam passes through a system of llenses and is directed and positioned by two highly precise mirrors.

Metal additive manufacturing, a specific branch of 3D printing, focuses on creating parts and components from metal powders or wires. This technology is particularly valued in industries where high-strength, precision-engineered metal parts are required. Key applications include:

The advantage of metal additive manufacturing lies in its ability to create complex geometries that are often impossible to achieve with traditional manufacturing methods, along with reduced waste and often shorter production times.

Ongoing advancements in this field are likely to further enhance the capabilities and applications of metal additive manufacturing, making it a critical technology in modern manufacturing and engineering.

Improvements in additively manufactured heat exchanger compared to traditional manufacturing include:

Higher Thermal Exchange - Enhanced surface area density to volume ratio results in high thermal exchange performance.

Reduced Weight - Monolithic structures result in significant weight reductions.

Reduced Size - Higher thermal performance and monolithic parts translate to step changes in part size

Low Pressure Drop - Optimised flow design reduces pressure drop and improves system efficiency.

Morphed Topology - Design freedom gives flexibility in form factor; geometry can be morphed to the fit the space available.

Learn more about how we have enhanced heat exchangers by reading our case studies

Heat exchangers produced via additive manufacturing offer significant performance benefits for a wide-ranging industries and applications. Including: higher thermal exchange, reduced weight, low pressure drop and morphed topology.

Additional benefits of additive manufacturing include:

Costs for additive manufacturing also known as 3D printing can vary greatly depending on the specific requirements of the project. To discuss your requirements, speak to one of our additive manufacturing specialists.

There are many materials commercially available. Common base metals are aluminium, iron, titanium, copper, nickel, chromium, gold, silver and more.

These are often alloyed to produce materials with properties desirable for the printing process, the finished goods or both. AlSi10Mg is a commonly used aluminium alloy that Conflux utilises. Steels have many varieties, the most common of which is 316. In high end heat applications, examples include Inconel (nickel chromium) or Monel K 500 (nickel copper) super alloys.

Conflux chooses the ideal material to solve our customers heat transfer requirements. Materials are chosen to suit the environment in which the heat exchanger will interact with the working fluids and mechanical system.

Conflux primarily uses AlSi10Mg due to its superior AM printing properties. Aluminum alloys offer the best balance of thermal conductivity, weight, strength and durability and are well suited to many applications.

Stainless Steel (316) is used for higher temperature applications and where greater strength and/or resistance to corrosion is required. Conflux is actively testing and qualifying new materials for our heat exchangers.

A heat exchanger is a system used to transfer heat between two or more fluids without mixing them. Common in industrial and commercial processes, it plays a vital role in heating, cooling, and waste heat recovery systems. Heat exchangers come in various designs, including shell and tube, plate, and finned types, catering to different temperature ranges and fluid properties. Key materials used include metals like stainless steel and aluminum, known for their thermal conductivity and corrosion resistance.

At Conflux, we specialize in 3D manufactured heat exchangers within the motorsport, automotive, aerospace, defence, energy and electronics industries.

News

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Media

Case Studies

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

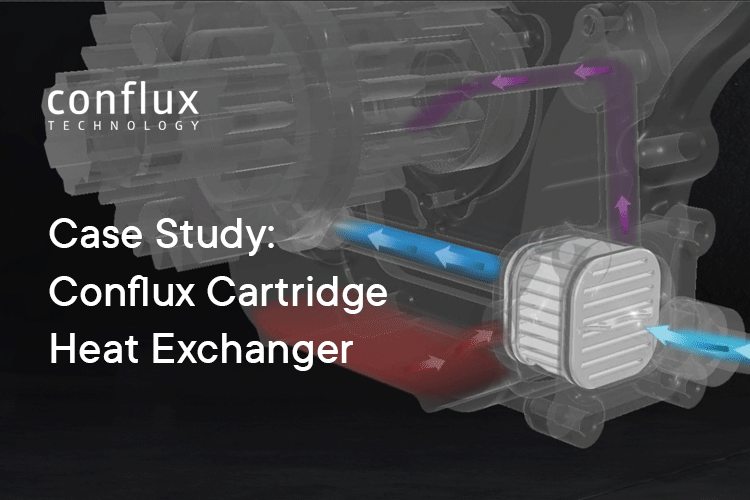

ケーススタディ :3Dプリント熱交換器Conflux Cartridge(コンフラックス・カートリッジ)

ケーススタディ :3Dプリント熱交換器Conflux Cartridge(コンフラックス・カートリッジ)

Case Study: Conflux Water Charge Air Cooler

Case Study: Conflux Water Charge Air Cooler