Read our latest article - AS9100D Certification: Elevating Standards in Heat Exchanger Manufacturing

With over two decades of experience in designing thermal management systems for high-performance industries, our team collaborates closely with clients to craft optimal solutions with minimal compromises, leveraging our comprehensive understanding of thermal management and cooling systems across various platforms. This systems-level knowledge enables a holistic approach to problem-solving, offering both direct replacement solutions and opportunities for part consolidation.

Specializing in the development of heat exchangers based on fundamental design principles, we push the boundaries of Additive Manufacturing (AM) technology to improve performance, encompassing concept development, design engineering, simulation, AM prototyping, manufacturing, post-processing, and testing. Our scalable and configurable heat exchanger products meet complex thermal challenges, tailored to each customer's specific conditions and requirements, ensuring high performance and lightweight solutions.

At Conflux, located just outside Melbourne, Australia, we provide a comprehensive end-to-end manufacturing service through vertical integration and a validated supply chain, encompassing design, simulation, testing, and manufacturing. Operating with multiple Laser Powder Bed Fusion (LPBF) systems and maintaining platform agnosticism, we continuously expand our manufacturing capabilities to meet and exceed customer expectations.

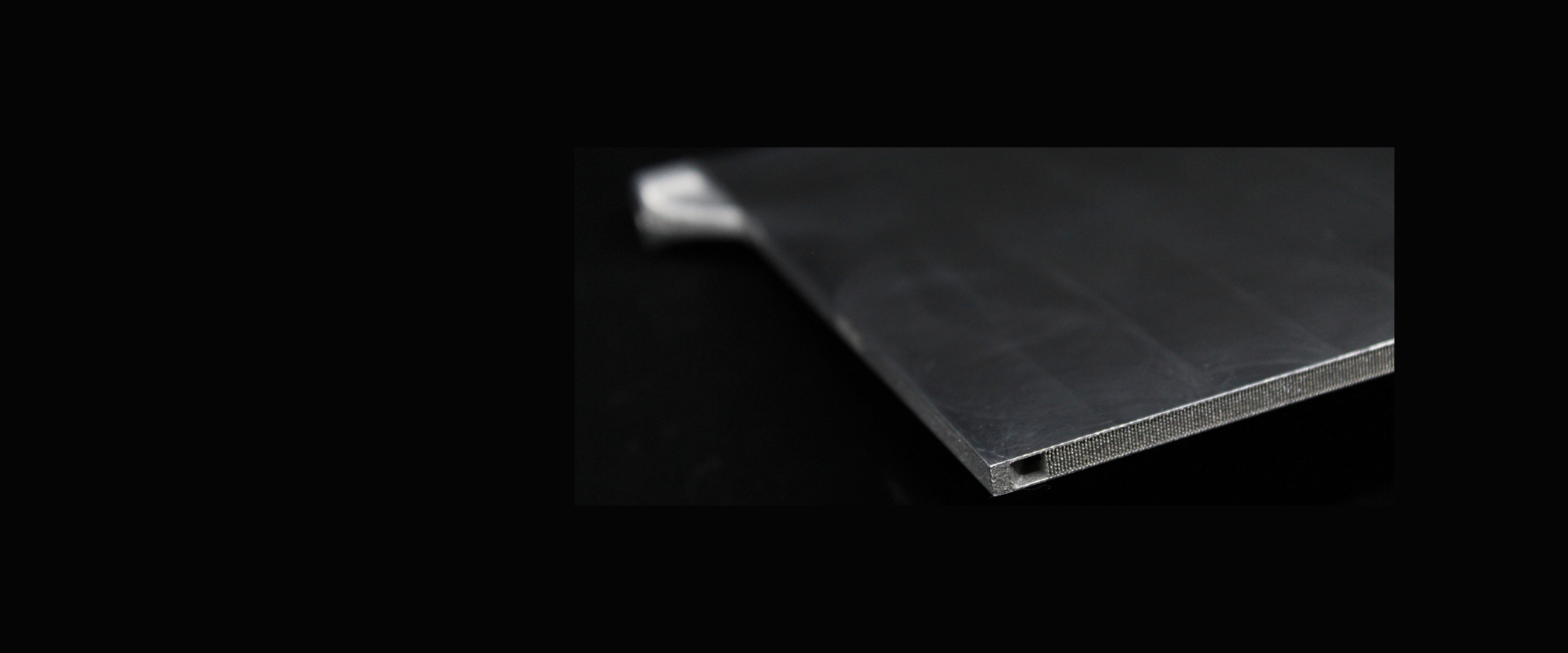

Conflux’s cold plate heat sink is ultra-lightweight and can conform to any cooling system.

Laser Powder Bed Fusion (LPBF) is what we use as our metal AM technology. LPBF uses a fibre laser to selectively melt fine metal powder in order to form the desired three-dimensional object. The laser beam passes through a system of lenses and is directed and positioned by two highly precise mirrors.

After a layer of powder is selectively melted, the build platform/part is lowered. Another layer of powder is spread across the part using a recoating mechanism and the laser melting process is repeated. This layer by layer process repeats itself until the final height of the part has been realised.

We have chosen laser powder bed fusion technology for its ability to create the highly dense, thin walled, complex features that are critical for the best performance in heat exchange.

To meet the needs of our wide requirements of customers, we work with a range of commercially available additive manufacturing materials in order to deliver high-end heat exchangers, including:

Our R&D department is continually researching new and novel materials for various thermal applications.

Utilising Design for Additive Manufacturing (DfAM) methods, our design process creates highly complex geometries grounded in fundamental principles, seamlessly integrating core heat transfer concepts with thermo-fluid simulations and an extensive understanding of AM processes. Our deep knowledge of AM technology, its best practices, and limitations allows us to maximize the potential of AM heat exchangers, achieving notable improvements in thermal efficiency.

Through the integration of Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) simulations, our approach enables precise prediction and enhancement of part performance by optimizing heat rejection and minimizing pressure drop, thanks to detailed analysis of heat flux and fluid dynamics. Multiphysics simulations play a pivotal role in our engineering processes, where our calculations engineers employ CFD to forecast performance and guide design decisions from an early stage, alongside FEA to assess structural integrity and durability against real-world conditions. This meticulous simulation not only projects performance metrics like heat rejection and pressure drop but also identifies optimal geometry for maximum heat transfer efficiency with minimal flow disruption. By correlating these simulations with empirical test data, we validate our models, providing a robust foundation for subsequent design refinement. This process ensures that our models become increasingly accurate, allowing for swift and effective optimization in design iterations, delivering superior performance tailored to customer needs.

Our unique thermal expertise:

In every industry we engage with, we encounter unique standards and certification requirements, leading to project-specific acceptance criteria. To navigate this, we devise testing and validation programs specifically designed to address the distinct challenges and objectives of each project.

From the conceptualization stage, Conflux prioritizes the validity of our work, incorporating considerations such as powder removal and end-use performance early on. This principle extends through to final performance testing, incorporating intermediate steps like pressure/leak testing and CT scanning to guide development, ensuring deliverables meet the brief without compromise and are delivered on schedule.

Our methodology involves strategic builds within rapid development cycles, assessing manufacturability through iterative evaluation and employing both physical and analytical testing methods to validate design integrity and optimize efficiency, thus mitigating risks en route to manufacturing full-scale, functional AM components.

Leveraging in-house and independent testing facilities, including unique access to ANSTO’s Australian Synchrotron, we verify prototype quality and performance. This process, enhanced by correlating test results with simulations via our Conflux Quantify software, initiates design optimization, enabling us to maximize performance potential and offer clients customized solutions.

Conflux maintains AS9100D certification, underscoring our commitment to quality and excellence in additive manufacturing.