Each industry uses a multitude of different types of heat exchangers. Additionally, cooling systems' complexity has increased substantially in recent times. Meaning, heat exchange performance has never been as critical as it is today.

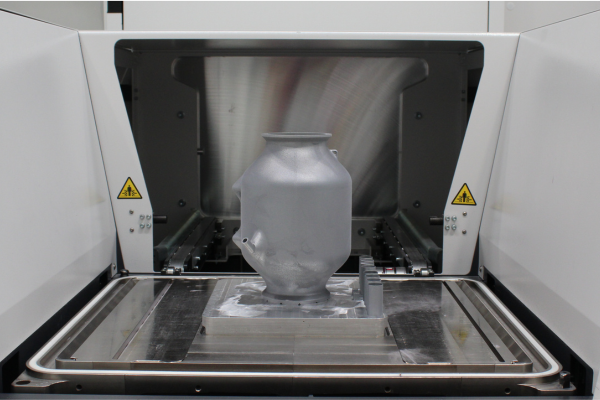

While traditionally manufactured heat exchangers definitely still have their place, due to their manufacturing techniques, they offer relatively basic and linear geometries. Which is fine for some tasks. However, when your priorities are overall performance, additive manufactured heat exchangers can offer you potential not yet conceived. For example, one of our most prevalent forms of thermal solutions is conforming to abstract spaces and increasing compactness whilst also improving or maintaining performance.

Conflux 3D printed heat exchangers offer a whole host of benefits, such as;

-Higher thermal exchange

-Reduced weight

-Low pressure drop

-Morphed topology

-Reduction of lead times

-Part consolidation

-Lower R&D costs

-And more.

Conflux Technology is leading the world in Additive Manufactured Heat Exchangers.