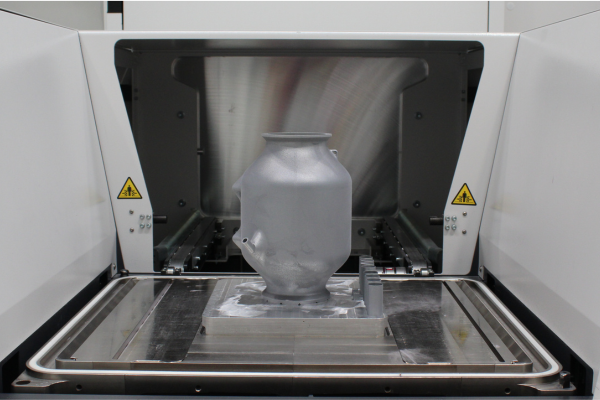

This is a common question - especially when we have so much freedom of design. External part shape or packaging volume, is often driven by customer requirements.

So, how do we decide the internal geometry? This is at the heart of our core competencies. Our deep knowledge of AM and heat exchangers translates to knowing how to adapt to the different boundary conditions rapidly.

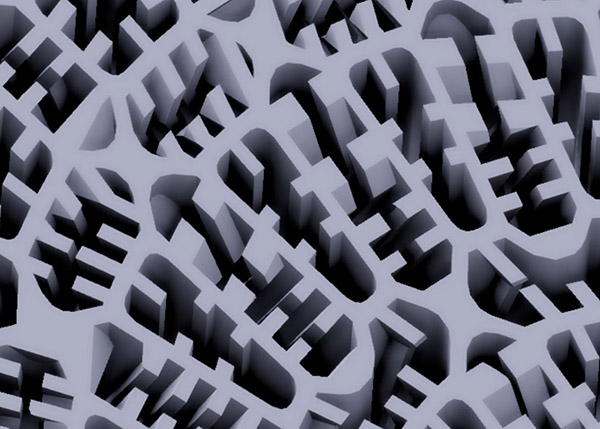

Through extensive internal R&D over several years, Conflux has built a considerable library of geometries that provide the optimum heat exchange performance in multiple scenarios. This forms the basis of our design and background IP. We use this library and accumulated knowledge to design use internal geometries. The form and geometries also evolve through the HEX as the fluids change in properties, to ensure that we are getting a very high efficiency through the entire device.